Tiếng Việt

Tiếng Việt-

English

English -

Tiếng Việt

Tiếng Việt

Không có sản phẩm

Giá đã bao gồm thuế

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

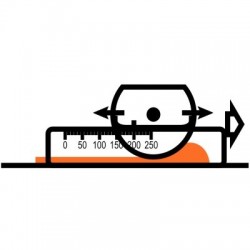

An essential machine for preparing a wide variety of product samples including paint, varnish, cosmetics, glue, etc. with total consistency and reproducibility on various substrates including contrast charts, sheet steel, plastic foils and glass. All Elcometer 4340 models have 11 pre-set speeds and adjustable stroke length with quick release system.

- Ideal for testing paint, varnish, cosmetics, glue etc.

- 11 preset transverse speeds, from 0.5-10cm per second

- Sample temperature control option

- High quality samples produced for highly reliable laboratory testing

- Smooth aluminium table - much smoother than glass - for better repeatability

- Can be used with Elcometer Film applicators

- Wide range of standard and high precision perforated and channelled vacuum tables

- Adjustable travel carriage with "stop" at end of travel

| Interchangeable head attachments Easily switched between film applicators - Spiral Bar Head Attachment - Standard Applicator Head Attachment - Combined Spiral/Standard Head Attachment |

| Durable & Rugged - Sturdy rigid design to ensure minimal movement during film application - Up to 15 years of standard use |

| Choice of Bed - Standard flat table - Single channel vacuum table - Double channel vacuum table - Perforated |

| Smooth & multiple concurrent tests - Use up to 3 film applicators simultaneously - Test up to 2 Leneta test charts simultaneously - Able to test up to 2 test areas on perforated tables |

The Elcometer 4340 Motorised Film Applicators are versatile, rugged and precise. The rigid construction ensures a smooth, consistent application without the ridges often associated with film application.

A range of applicator head attachments is available separately, allowing the user to select the most appropriate for their specific use and Standard (if applicable).

The Elcometer 4340 range of motorised Film Applicators comes as one universal base with user selectable head attachments - allowing the flexibility to test using standard film applicators (filmographs), spiral bar coaters, or using the combined attachment of both the film applicator and spiral bar attachment.

Available with a highly engineered table, available with or without a vacuum and heating element, each Elcometer Motorised Film Applicator is accurately measured using a Co-ordinate Measuring Machine to meet an incredibly high level of flatness. (Vacuum tables offer more reproducibility).

The average variation on Elcometer Application Tables is 2.3µm (0.092mil), while the average variation on glass used on some low cost tables is 12.0µm (0.48mil).

If a 100µm (4mils) coating is tested, readings taken using an Elcometer table would produce readings between 97.7 (3.9mils) and 102.3µm (4.1mils). On glass, the readings produced would be between 88 (3.5mils) and 112µm (4.48mils) - a 47% variation.

No customer comments for the moment.

Related Products